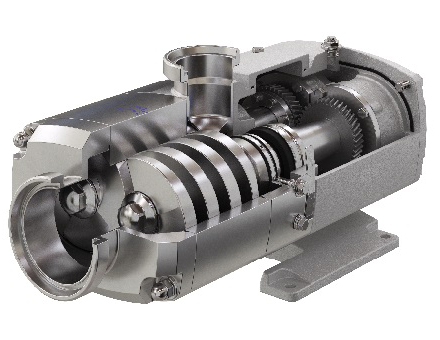

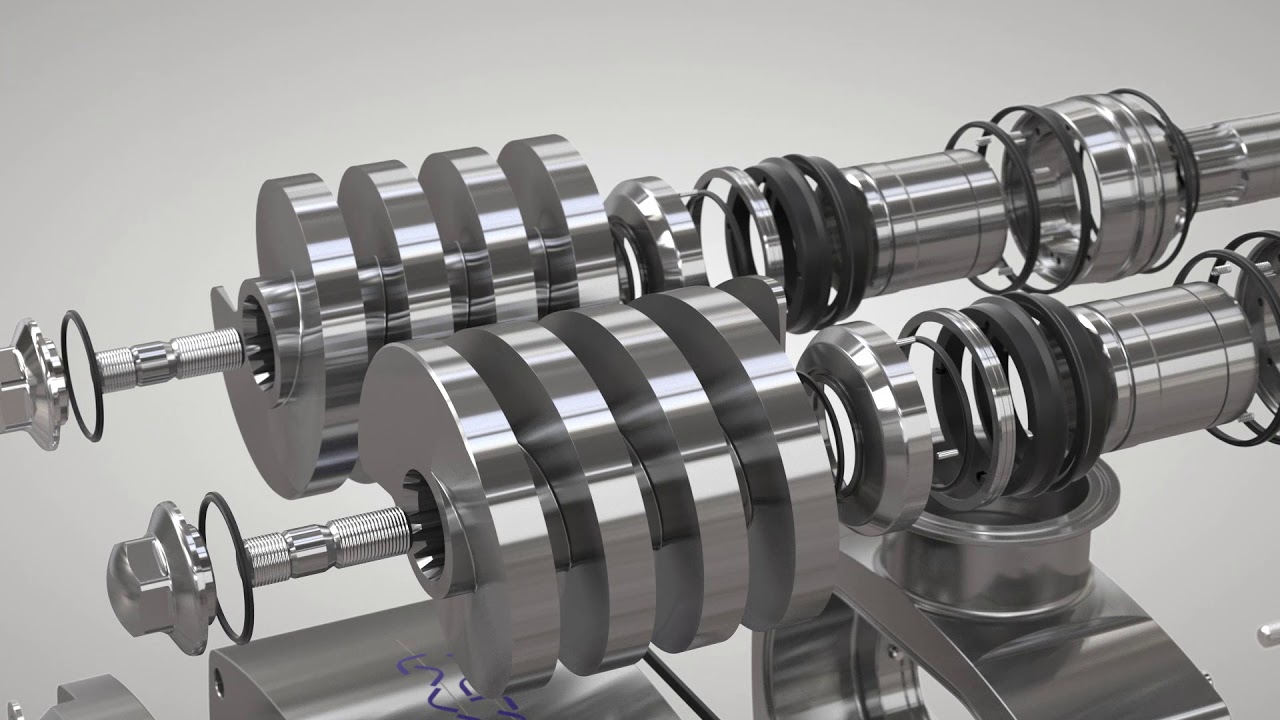

Designed for handling sensitive, abrasive and high and low viscosity fluids, the Alfa Laval Twin Screw Pump is ideal for use in hygienic applications in the dairy, food, beverage and personal care industries. Its quiet, virtually pulse-free, smooth and gentle operation makes the pump an excellent choice for handling sensitive products.

High and low viscosity liquids – all perfectly and reliably pumped

- Greater process flexibility

- Ease of service, increased process uptime

- Robust reliable design, reducing cost of ownership and increasing process uptime

- Improved product quality

- Exceptional hygiene and cleanability

Hotline: +84 906 803 393

Hotline: +84 906 803 393

Product detail

-

Product codeAlfa Laval Twin Screw Pump

-

CAPACITYup to 120 m3/h

-

APPLICATIONSAlfa Laval Twin Screw Pump is ideal for use in hygienic applications in the dairy, food, beverage and personal care industries.

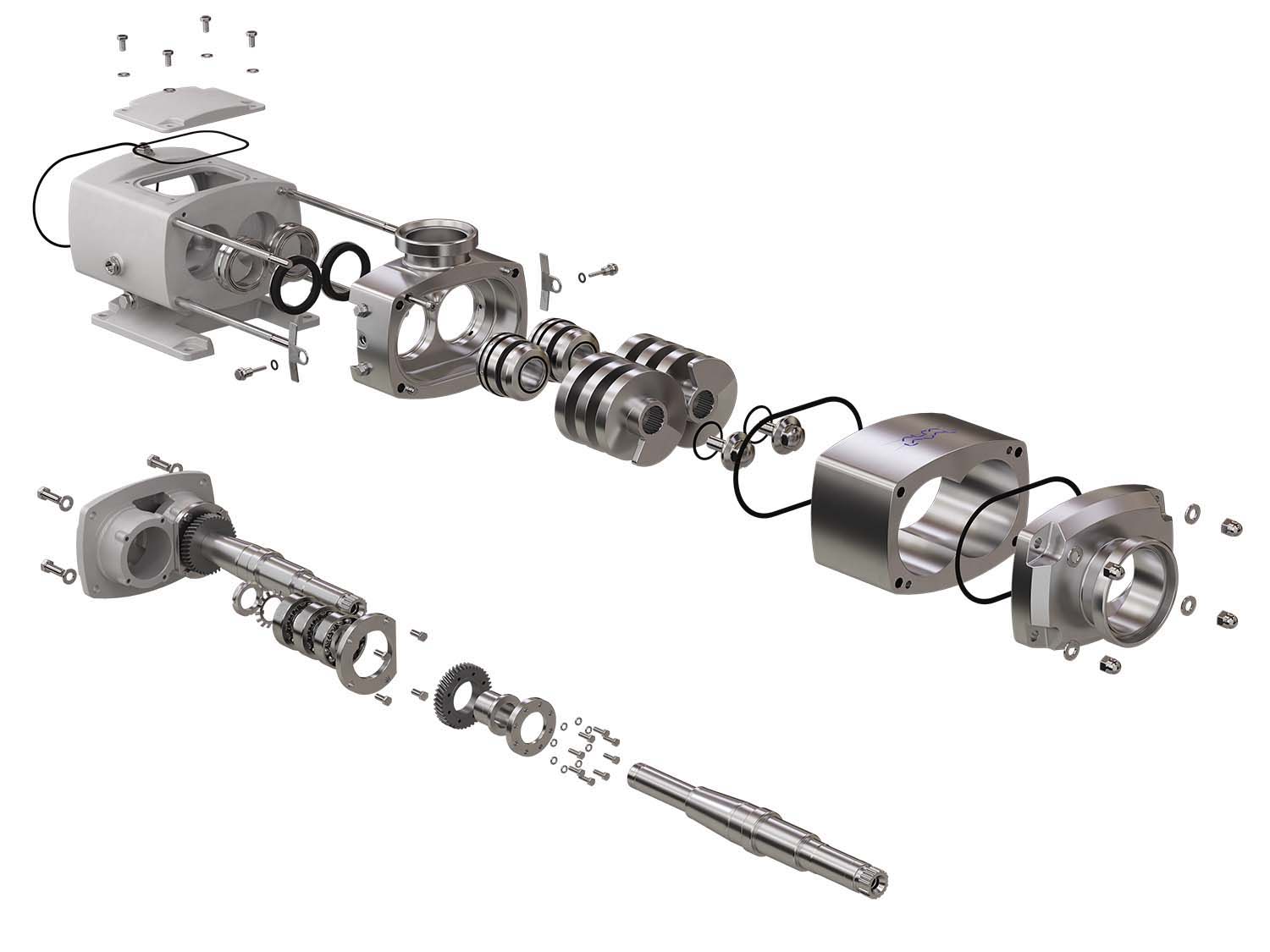

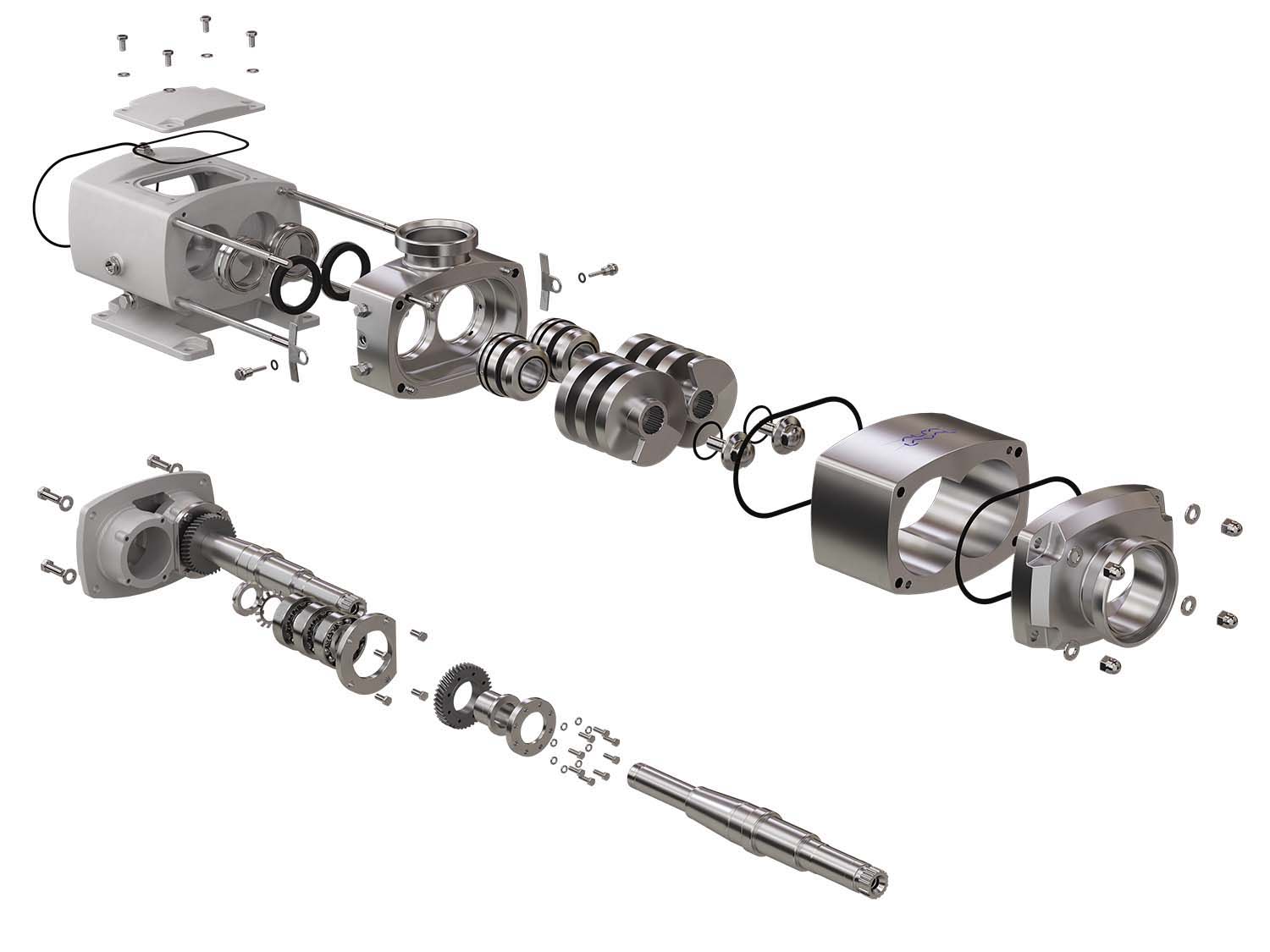

Twin Screw Pump technology

The Alfa Laval Twin Screw Pump combines process duties typically handled by positive displacement with CIP duties typically handled by centrifugal pumps. This provides a robust and reliable platform that offers greater process flexibility.

Process flexibility

Two-in-one operation provides easy handling of process media of varying viscosities as well as CIP fluids. This simplifies piping and pump control, cutting costs and minimizing contamination risks.

Superior suction performance with excellent lift capability and low NPSHr provides installation flexibility and increases product recovery.

Service and reliability

Quick, easy seal replacement with the pump in place is made possible, thanks to a cartridge seal with a truly front-loading, self-setting design. This maximizes process uptime and minimizes maintenance costs. An optional seal service kit program adds maintenance flexibility and cuts operating costs.

Technical specifications

-

Product codeAlfa Laval Twin Screw Pump

-

CAPACITYup to 120 m3/h

-

APPLICATIONSAlfa Laval Twin Screw Pump is ideal for use in hygienic applications in the dairy, food, beverage and personal care industries.

Standard materials

Pump casing . . . . . . . . . . . . . . . . . W. 1.4404 (316L), diffusion hardened

Screws, front cover, seal housing: . . . W. 1.4404 (316L)

Product wetted elastomers: . . . . . . . EPDM

Other elastomers: . . . . . . . . . . . . . . FPM

Shaft seal: . . . . . . . . . . . . . . . . . . . Single flush, Silicon Carbide/Silicon Carbide

Gear box: . . . . . . . . . . . . . . . . . . . Stainless steel

Base plate: . . . . . . . . . . . . . . . . . . Stainless steel

Coupling guard: . . . . . . . . . . . . . . . Stainless steel

Operational safety

The Alfa Laval Twin Screw Pump features a clean, external stainless steel finish with profiled elastomers and mechanical seals fully surrounded by the product. Designed for maximum cleanability using FDA-conforming materials, the pump is both EHEDG- and 3-A certified.

The combination of optimized gearbox design and excellent hydraulic performance provides for quiet pump operation, minimizing noise emissions. Running temperature is also minimized, thereby increasing workplace safety.

Quick, easy maintenance

Minimize maintenance costs and maximize process uptime. Seal replacement with the pump in place is quick and easy, thanks to a cartridge seal with a truly front-loading, self-setting design. An optional seal service kit provides maintenance flexibility and cuts costs. Easy access to timing gears whilst the pump is in position simplifies the process of screw retiming without requiring drainage of the gearbox oil or removal of the coupling and motor.