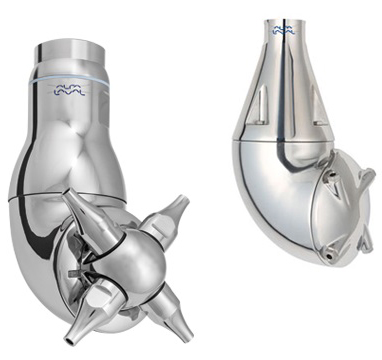

Alfa Laval’s range of Rotary Jet Head tank-cleaning devices provide exceptional cleanability, better end-product quality, greater overall output and up to 70% reduction in operating costs. They are designed for hygienic applications, such as food, dairy, personal care and beverages.

High impact quality assured cleaning in a 360° repeatable cleaning pattern

- Avoid contamination with effective cleaning performance and superior self-cleaning features

- Cost efficient and sustainable solution due to reduced water and chemicals requirements

- More available production time because of reduced cleaning time

- Easy to service and maintain – no special tools required

- Control of CIP through validated cleaning

Hotline: +84 906 803 393

Hotline: +84 906 803 393

Product detail

-

Product codeAlfa Laval’s Rotary Jet Head

-

APPLICATIONSThey are designed for marine, hygienic, biotechnology and pharmaceutical applications

TJ

Engineered for use in the hygienic industries, Toftejorg rotary spray heads from Alfa Laval are highly efficient tank-cleaning offer exceptional cleanability, better end-product quality, greater overall output and reduced operating costs.

Sani SB 3-A Rotary Spray Head is preliminary designed for the pharmaceutical industry with respect to self-cleaning, self-draining and inspectability. Its novel patent pending one-clip assembly offers easy installation, disassembly and inspection without compromising cleanability or drainability.

SaniJet

Alfa Laval SaniJet is designed for hygienic, biotechnology and pharmaceutical applications and provide exceptional cleanability, better end-product quality, greater overall output and reduced operating costs.

Benefits of Alfa Laval SaniJet rotary jet head

- 60% faster cleaning = more time for production

- High impact cleaning in a 360° repeatable cleaning pattern

- Control of CIP through validated cleaning

- Saves up to 70% of your cleaning cost

- Hygienic safety by reliable and predictable cleaning performance

T/TZ Rotary Jet Head

Alfa Laval T/TZ Rotary Jet Head tank-cleaning range provide exceptional cleanability, better end-product quality, greater overall output and reduced operating costs. They are designed for hygienic applications such as food, dairy and beverage as well as for the marine environment. Available in various sizes and different configurations covering any tank size.

The Alfa Laval GJ A

The Alfa Laval GJ A product line offers tank cleaning devices that deliver powerful, efficient, hygienic cleaning for companies within the food, beverage and personal care industries. They are ideal for retrofit applications to replace resource-heavy static spray balls and costly manual cleaning. Features of the GJ A includes self-cleaning and self-draining capabilities and the ability to clean tanks through openings as small as a 5cm (2”).

Technical specifications

-

Product codeAlfa Laval’s Rotary Jet Head

-

APPLICATIONSThey are designed for marine, hygienic, biotechnology and pharmaceutical applications

MultiJet

Alfa Laval MultiJet Rotary Jet Head tank-cleaning range provide exceptional cleanability, better end-product quality, greater overall output and reduced operating costs.

They are designed for industrial application, such as paint, steel, Pulp & Paper, chemical applications. Available in various sizes and different configurations covering any tank size.

Barrel/Drum/IBC

The Alfa Laval GJ 7, Alfa Laval GJ BB and Alfa Laval GJ 9 rotary jet head tank cleaning devices represent a major technological breakthrough, offering the most powerful cleaning results in a compact, easy to handle size.

The Alfa Laval GJ 7 and Alfa Laval GJ BB are specially designed to clean small barrels and drums, while the Alfa Laval GJ 9 offers fast cleaning of your intermediate bulk containers (IBC).

i65 S

The Gunclean Toftejorg i65 S is a fully programmable single-nozzle tank cleaning machine equipped with an innovative hysteresis clutch.