Ideal for the dairy, food and beverage industries, this cost-effective dual-stage inline powder dissolution unit quickly mixes and pumps wet and dry ingredients into a homogeneous blend.

Hotline: +84 906 803 393

Hotline: +84 906 803 393

Product detail

-

Product codeAlfa Laval Hybrid Powder Mixer

-

CAPACITY3000 kg/h capacity for skimmed milk powder

-

APPLICATIONSDairy, beverage and food powder mixing applications

Hybrid Powder Mixer

Ideal for the dairy, food and beverage industries, this cost-effective dual-stage inline powder dissolution unit quickly mixes and pumps wet and dry ingredients into a homogeneous blend.

The Alfa Laval Hybrid Powder Mixer is a patented hygienic mobile unit that both disperses powders into liquids quickly and efficiently and pumps the resulting solution at outlet pressures of up to ~5 barg, all using a single motor. This versatile, easy-to-use mixer produces homogeneous products at high dry matter concentrations and high productivity.

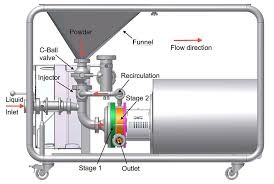

Design

The Alfa Laval Hybrid Powder Mixer is comprised of a two stage pump with one rotor-stator stage and one pump stage. The unit is fitted with a single motor and a frequency converter. A funnel is used for introduction of powder through an injector system which can be isolated using a hygienic C-Ball valve. The construction is mounted on a stainless steel frame and the liquid inlet is equipped with a sight glass and a butterfly valve.

Technical specifications

-

Product codeAlfa Laval Hybrid Powder Mixer

-

CAPACITY3000 kg/h capacity for skimmed milk powder

-

APPLICATIONSDairy, beverage and food powder mixing applications

Hybrid Powder Mixer

The mixer is an excellent choice for use in a wide range of dairy, beverage and food powder mixing applications, e.g. for incorporating thickeners and stabilizers like pectin and xanthan and emulsifiers in the concentrations required in most applications. It is also capable of producing recombined milk with more than 50% dry matter.

Technical data:

Temperature range: . -10°C to + 95°C (Max. at CIP)

Temperature,Media,Maximum: . . . 70°C

Recommended inlet pressure: . . . . 0.0 - 0.2 bar

Min. back pressure recommended: . . 1 barg

Dry ingredient capacity: . . . Dependent on powder (e.g. 3000 kg/h capacity for skimmed milk powder).

Noise level (at 1m): . < 90 dB(A)

Operation of the Alfa Laval Hybrid Powder Mixer

The two-stage in-line Hybrid Powder Mixer is installed in a recirculation loop connected to a batch tank. This user-friendly mobile unit has a built-in table to facilitate handling of heavy bags of powder. The table easily slides into position for convenient placement of the bags during mixing.

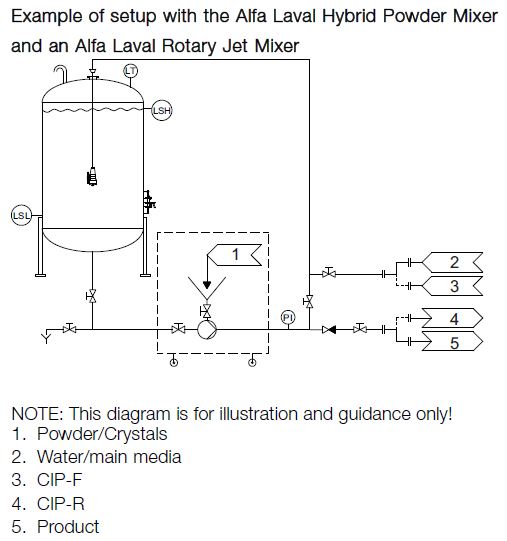

After adding liquid ingredients to the tank, the Alfa Laval Hybrid Powder Mixer is used to circulate the liquid over the tank. To provide high-efficiency mixing in tanks with volumes larger than 1 - 2 m³ it is recommended to install an Alfa Laval Rotary Jet Mixer in the tank by connecting it to the end of the circulation pipe.

After powder is introduced in the funnel, the C-Ball valve under the funnel is opened. The valve is the only component that the operator must control during introduction of the powder. The injector positioned under the valve creates an under pressure in the funnel outlet, drawing the powder into the rotor-stator stage of the pump and blending the powder and liquid into a homogeneous mixture. The impeller in the second stage of the pump transfers the powder-liquid mixture back to the tank while part of the powder-liquid mixture is sent through the injector creating the under pressure in the funnel outlet, which enables the suction of the powder into the liquid.

When mixing is complete, the Hybrid Powder Mixer may be used as a discharge pump or, when used with the Alfa Laval Rotary Jet Mixer, as a CIP forward pump – depending on the size of the tank and Rotary Jet Mixer – to clean the tank interior.