The removal of entrained liquids in steam, compressed air and gas systems

Hotline: +84 906 803 393

Hotline: +84 906 803 393

Product detail

-

Product codeSteam separators - Spirax Sarco

-

APPLICATIONSThe removal of entrained liquids in steam, compressed air and gas systems

S1 SG Iron Separator

The S1 is a cast SG iron baffle type separator used for the removal of entrained liquids in steam, compressed air and gas systems. The fitting of insulation jackets will increase the performance of the separator.

Standards: This product fully complies with the requirement of the Indian Boiler Regulations, 1950.

Certification: This product is available with a manufacturers' Typical Test Report and IBR certification. Note: All certification/inspection requirements must be stated at the time of order placement.

S5 & S7 Carbon Steel Separator

The S5 is a carbon steel baffle type separator used for the removal of entrained liquids in steam, compressed air and gas systems.

Certification: This product is available with a manufacturers 'Typical Test Report and IBR

Certification: Note: All certification / inspection requirements must be stated at the time of order placement. Sizes and pipeline connections DN65, DN80, DN100, DN125, DN150, DN200, DN250, DN300 and DN350. Flanged ASME B16.5 Class 150 and 300 with screwed NPT vent and drain connections.

Technical specifications

-

Product codeSteam separators - Spirax Sarco

-

APPLICATIONSThe removal of entrained liquids in steam, compressed air and gas systems

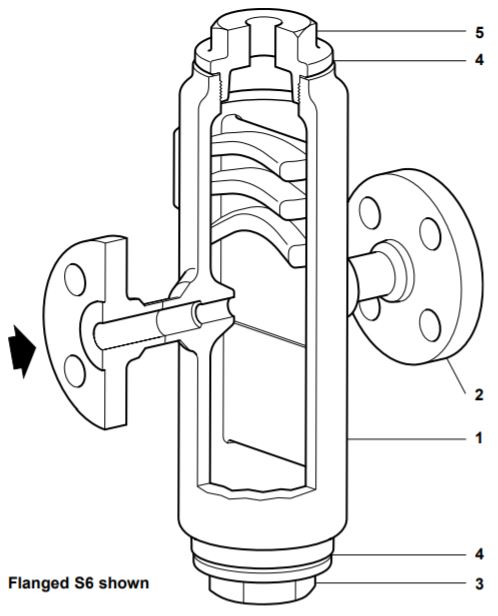

S6 Stainless Steel Separator

The S6 is an austenitic stainless steel (316L) baffle type separator used for the removal of entrained liquids in steam, compressed air and gas systems.

Standards: This product fully complies with the requirements of the Pressure Equipment Directive PED and carries the mark when so required. The product has been specifically designed for use on steam and compressed air, which are in Group two of the above mentioned PED.

Certification: This product is available with certification to EN 10204 3.1. Note: All certification / inspection requirements must be stated at the time of order placement.

S13 SG Iron Separator (Flanged)

The S13 separator is an SG iron baffle type separator used for the removal of entrained liquids in steam, compressed air or gas systems. The fitting of insulation jackets will increase the performance of the separator.

Standards: This product fully complies with the requirements of the Pressure Equipment Directive (PED).

Certification: This product is available with a manufacturers' Typical Test Report. Note: All certification/inspection requirements must be stated at the time of order placement.