Alfa Laval LeviMag magnetic mixers offer effective mixing for multiple processes within Dairy, Beverage and Food applications - eg. aseptic or sterile storage or buffer tanks - where high demands on hygienic and aseptic design are required.

Due to the compact design the LeviMag is also an obvious choice for low level agitation.

Hotline: (84.0) 906 803 393

Hotline: (84.0) 906 803 393

Product detail

-

Product codeMagnetic mixer

-

CAPACITYDepending on duty and media properties the LeviMag can be configured to be used in tanks from 30 l. to 40.000 l.

-

APPLICATIONSDairy, Beverage and Food applications

Maximize process economy, minimize product loss

- Optimized flow with higher efficiency and less energy consumption

- Mixing down to the last drop for maximum yield due to low agitation and dry-running capability

- Optimized Cleaning-in-Place thanks to full drainability

- Minimized downtime due to ease of maintenance

Technical specifications

-

Product codeMagnetic mixer

-

CAPACITYDepending on duty and media properties the LeviMag can be configured to be used in tanks from 30 l. to 40.000 l.

-

APPLICATIONSDairy, Beverage and Food applications

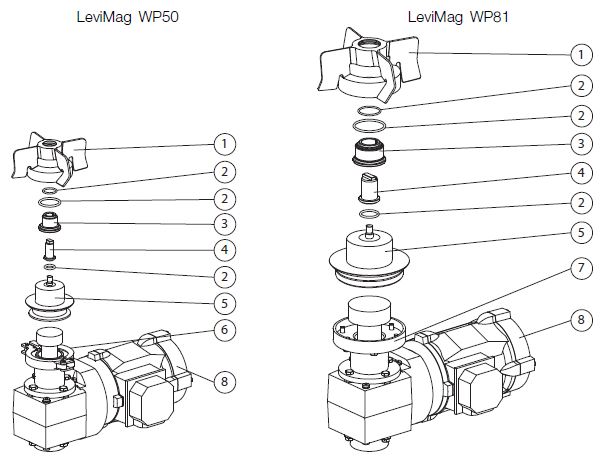

Build up:

Build up:

1. Impeller

2. Seals

3. Female Bearing

4. Male Bearing

5. Weld Plate

6. Clamp ring connection (WP50 only)

7. Flange-Bolt Connection (WP81 only)

8. Drive unit

Unique features

- Levitated design: Makes the bearing fully drainable and minimize wear of the bearing.

- Replacable bearings: Both the female and the male bearing can be replaced by the end user on site.

- High efficiency impeller: The impeller unit is flow optimized, which creates the possibily of gentle product treatment

- Mixing to last drop: Dry running capability makes it possible to achieve maximum yield.