Benefits

• Compact

• Easy to install

• Self-cleaning

• Low level of service and maintenance is required

• All units are pressure and leak tested

• Gasket free

Hotline: (84.0) 906 803 393

Hotline: (84.0) 906 803 393

Product detail

-

Product codeAlfa Laval: CB110

-

APPLICATIONSHVAC heating and cooling, Refrigeration, Oil cooling, Industrial heating and cooling

Design

The brazing material seals and holds the plates together at the contact points ensuring optimal heat transfer efficiency and pressure resistance. Using advanced design technologies and extensive verification guarantees the highest performance and longest possible service life.

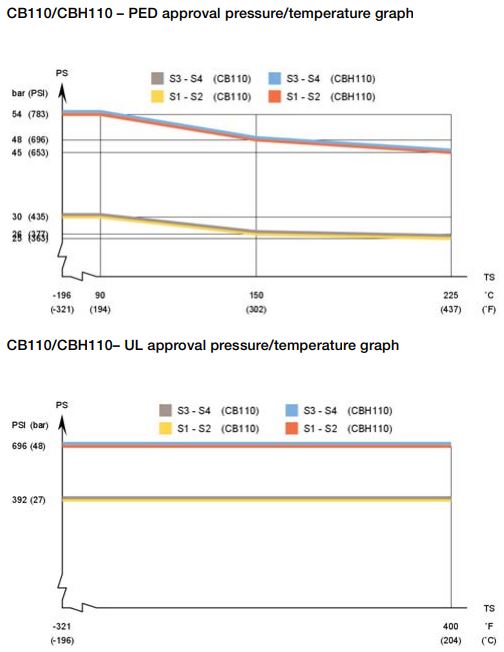

Different pressure ratings are available for different needs.

Based on standard components and a modular concept, each unit is custom-built to meet the specific requirements of each individual installation

Sustainable heat transfer

- Lightweight brazed construction offers much greater thermal efficiency than comparable shell-and-tubes with a footprint that’s 75% smaller

- The flexible DynaStatic distribution system in AC models enables higher efficiency in any evaporator duty and with any refrigerant

- Alfa Laval’s FlexFlow plate design provides channel asymmetry that can be tailored to fit the application

- We help you select the optimal pressing depth, plate pattern and configuration for your application

- An ideal solution for use with natural refrigerants, thanks to the compact footprint, optimized plate design and high design pressure

Higher efficiency. Smaller footprint.

Does your operation still rely on bulky, old-fashioned shell-and-tube heat exchangers for heating or cooling in your processes?

Are you curious to learn about the benefits of switching to brazed designs? Brazed plate heat exchanger technology offers significantly higher thermal efficiency than comparable shell-and-tube models, within a much smaller footprint. Among other things, this can help you reduce energy consumption, increase your heat recovery potential, and resolve space and bottleneck issues in your plant. Ready to take the next step?

Visit our Heating & Cooling Hub today to find tools and information to help you identify the right solution for your operation.

Technical specifications

-

Product codeAlfa Laval: CB110

-

APPLICATIONSHVAC heating and cooling, Refrigeration, Oil cooling, Industrial heating and cooling

Standard materials

Cover plates Stainless steel

Connections Stainless steel

Plates Stainless steel

Brazing filler Copper

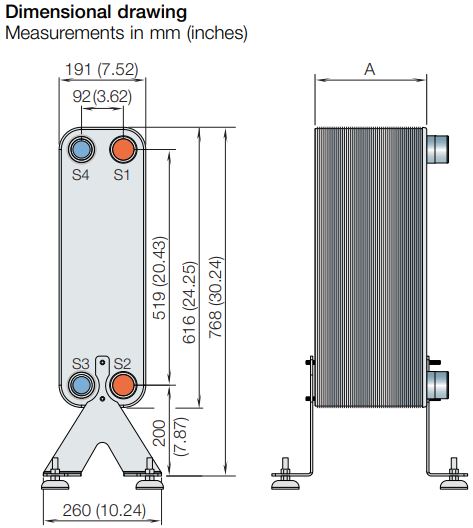

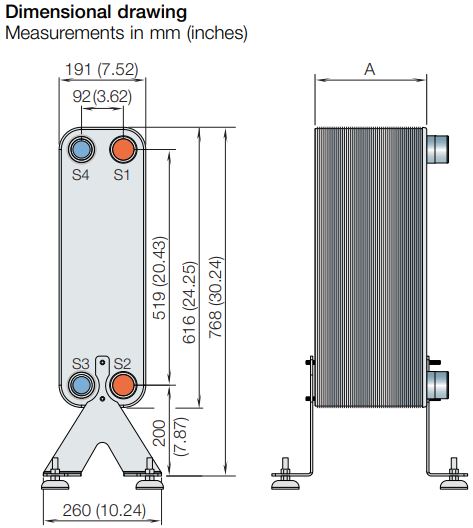

Dimensional drawing

Design pressure and temperature

Connections