Strainer designed to remove rust, scale and other debris from the pipeline

Hotline: (84.0) 906 803 393

Hotline: (84.0) 906 803 393

Product detail

-

Product codeStrainers - Spirax Sarco

-

APPLICATIONSStrainer designed to remove rust, scale and other debris from the pipeline

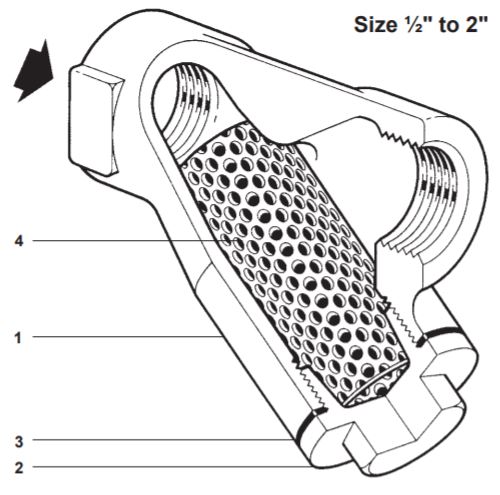

Fig 12 SG Iron Strainer

The Fig 12 is an SG iron screwed Y-type strainer. The standard stainless steel screen is 0.8 mm perforations. As options, other perforations and mesh sizes are available as well as monel screens. The strainer cap can be drilled and tapped for blowdown and drain valves if required

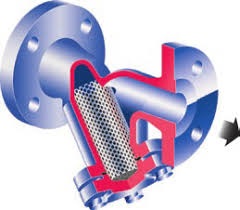

Fig. 34 Carbon Steel Strainer

The Fig 34 is an integrally flanged Y-type strainer designed to remove rust, scale and other debris from the pipeline. It is produced from carbon steel, ASTM material.

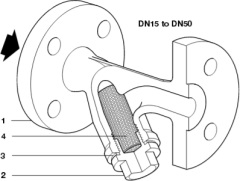

Fig 37 SG Iron Strainer

The Fig 37 is an SG iron integrally flanged Y-type strainer. The standard stainless steel screen in the DN15 to DN80 size range is 0.8 mm perforations, in the DN100 to DN200 it is 1.6 mm perforations.

As options other perforations and mesh sizes are available as well as monel screens. The strainer cap can be drilled and tapped for blowdown and drain valves if required.

Technical specifications

-

Product codeStrainers - Spirax Sarco

-

APPLICATIONSStrainer designed to remove rust, scale and other debris from the pipeline

Fig 12 SG Iron Strainer

Standards: This product fully complies with the requirements of the European Pressure Equipment Directive 97/23/EC.

Certification: This product is available with a manufacturers' Typical Test Report. Note: All certification/inspection requirements must be stated at the time of order placement.

Sizes and pipe connections ½", ¾", 1", 1¼", 1½", 2", 2½" and 3" screwed BSP or NPT.

Fig. 34 Carbon Steel Strainer

Standards: This product fully complies with the requirements of the European Pressure Equipment Directive 97/23/EC.

Certification: The product is available with material certification to EN 10204 2.2 as standard and EN 10204 3.1.B for body and cap by order.

Note: All certification/inspection requirements must be stated at the time of order placement.

Fig 37 SG Iron Strainer

Standards: This product fully complies with the requirements of the Indian Boiler Regulations, 1950.

Certification: The product is available a manufacturers' Typical Test Report and IBR Certification. Note: All certification/inspection requirements must be stated at the time of order placement.

Sizes and pipe connections DN15 to DN150 standard flange EN 1092 PN40 and ANSI 150. DN200 standard flange EN 1092 PN25 and ANSI 150.