With Alfa Laval Unique Sampling Valves you can take representative samples in a variety of hygienic processes including food and beverage, personal care and biopharm. These reliable single and double-seat valves provide the high accuracy, exceptional reproducibility and excellent reliability required for high quality, cost-effective sampling. The ergonomically designed handle ensures exceptional control and convenience during operation.

Hotline: (84.0) 906 803 393

Hotline: (84.0) 906 803 393

Product detail

-

Product codeAlfa Laval Unique Sampling Valve

-

APPLICATIONSHygienic processes including food and beverage, personal care and biopharm

Aseptic and sterilizable solution for safe sample collection

- Design ensures hygienic and contamination-free sampling

- Easy to operate thanks to simple working principle

- Highly reliable operation (rated to 10 bar) and three year warranty for all non-wearing parts

- Safe sampling through features such as non-return, quick couplings, pressure relief valve for steam and more

- Enhanced cleanability - valve body made of single piece of stainless steel provides smooth, crevice-free surfaces eliminating bacterial build-up risk

Standard design

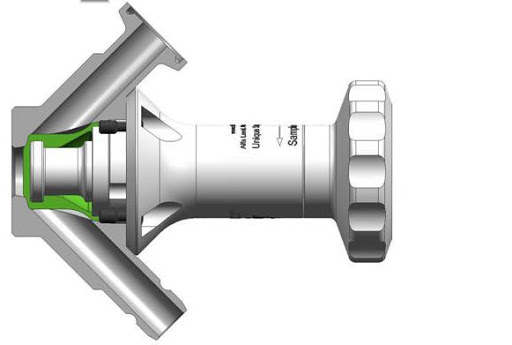

The valve consists of three parts, a valve body, an actuator and a membrane seal. The rubber membrane seal is placed on the stem of the actuator and works as a stretchable plug.

The valve bodies and actuators are interchangeable. The single seat valve can be upgraded to a double seat valve by replacing the handle or actuator with an upgrade kit - see ordering leaflet for accessories.

Technical specifications

-

Product codeAlfa Laval Unique Sampling Valve - Single Seat

-

TemperatureTemperature range: . . . . . . . . . . . . 1°C - 130°C

Max. sterilisation temperature, dry steam(2 bar) . . . . . . . . . . . . . . 121°C -

PressureMax. working pressure: . . . . . . . . . 600 kPa (6 bar)

Min. working pressure: . . . . . . . . . . 0 kPa (0 bar)

Materials

Valve body: . . . . . . . . . . . . . 1.4404 (316L) with 3.1 cert.

Actuator: . . . . . . . . . . . . . . . 1.4301 (304), 1.4404 (316L)

Membrane seal: . . . . . . . . . .EPDM, silicone

The valve is available in tree sizes:

Size 4 for low-viscosity products such as water, beer, wine and liquid milk. Viscosity: (cP) 0100. Max. particle size: 2.5mm (0.098 in)

Size 10 for high-viscosity products such as fruit yoghurt, syrup and ice cream. Viscosity: (cP) 01000. Max. particle size: 7mm (0.276 in)

Size 25 is for products with very high viscosity such as jam. Max. particle size: 20mm (0.787 in)

Unique single-seat sampling valves

Designed for standard hygienic sampling, the single-seat sampling valve has two positions: open and shut. It can easily be upgraded to a double-seat valve by replacing the handle or actuator with an upgrade kit.

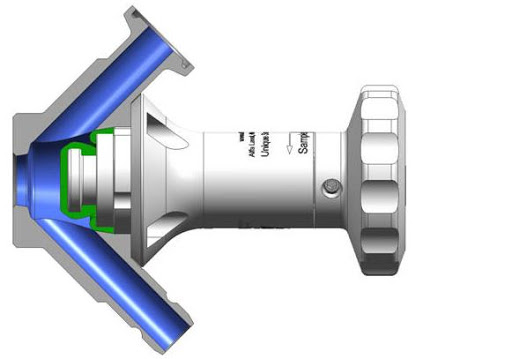

Unique double-seat sampling valves

The specially engineered Unique double seat sampling valves are an excellent choice for applications that require higher cleanability. Its patented double seat technology ensures higher cleanability and sterilization of the valve seat and pipe connections. Designed for truly sterile sampling, the double-seat sampling valve has three positions: open, shut and sterilization.