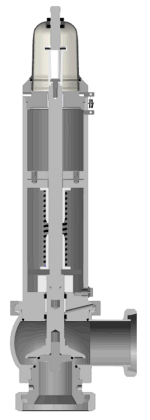

The Alfa Laval Safety Valve protects your equipment, your environment, and the health and safety of your workers.

This safety device is designed to open and relieve excess pressure from vessels or equipment and then reclose and prevent the further release of fluid when the system returns to normal.

Hotline: (84.0) 906 803 393

Hotline: (84.0) 906 803 393

Product detail

-

Product codeSafety Valve

-

APPLICATIONSDairy, food and beverage, and biopharm industries

Concept

The Alfa Laval Safety Valve is a spring loaded safety valve used to prevent overpressure in tanks and vessels in the dairy, food and beverage, and biopharm industries to reliably avoid damages to human beings and equipment.

Working principle

It is used to prevent inadmissible over pressures of fluids in tanks, containers and plant sections. From the factory the valve is configured with a set pressure upon request that is greater than the operating pressure. The valve opens against a spring force if the operating pressure increases the set pressure.

Preferably, the Alfa Laval Safety Valve should be installed vertically. If mounted horizontal the set pressure will be a bit lower than specified due to the missing weight of the piston. Highest effect on DN80 and DN100.

Standard Design

The Alfa Laval Safety Valve comes in sizes from DN25 to DN100 with spring loaded set pressure range from 0.2 to 12 bar.

The valve can be pneumatic or manually operated. Alfa Laval Safety Valve is delivered with PED certificate. Compliance to EN 4126-1 Compliance to PED 2014/68/EC of the European Community. Fluid group II (Non-hazardous fluids).

Technical specifications

-

Product codeSafety Valve

-

TemperatureTemperature range: . . . . . . . . . . . . . . . . .+5°C to +95 °C

Max. sterilisation temperature, dry steam: . .140 °C -

APPLICATIONSDairy, food and beverage, and biopharm industries

Materials

Product wetted parts: . . . . . . . . . . . 1.4404 (316L)

Other steel parts: . . . . . . . . . . . . . . 1.4301 (304)

Seals: . . . . . . . . . . . . . . . . . . . . . . EPDM

External finish: . . . . . . . . . . . . . . . . Ra 1.5-2.5 μm

Internal finish . . . . . . . . . . . . . . . . . Ra 0.8 μm

Connections: . . . . . . . . . . . . . . . . . Liner/nut -male DIN 11851

Option:

Inductive sensor for feedback is available for standard and pneumatic

lifting - see instruction manual for detail.