The Aseptic mixproof valve separates two process lines from one another by a steam barrier chamber. The aseptic steam valve and aseptic condensate valve (one NC and one NO) are integrated into the valve. Seat lifting can be performed on the product valves.

Benefits

• Exceptional hygiene for maximum product safety and minimal product loss

• Outstanding flexibility and modularity to meet virtually any requirement

• More uptime due to exceptional cleanability

• Up to 45% lower total cost of ownership compared to other aseptic valves

• Ease of maintenance and parts replacement

Hotline: (84.0) 906 803 393

Hotline: (84.0) 906 803 393

Product detail

-

Product codeAlfa Laval Aseptic Mixproof Valve

-

APPLICATIONSThis aseptic double-seat mixproof valve is designed for use in aseptic process applications across the dairy, food, beverage, and many other industries.

Standard design

The Alfa Laval Aseptic Mixproof Valve is a normally closed (NC) valve controlled from a remote location by means of compressed air. An integrated valve plug/diaphragm ensures aseptic operation. There is a total of four valves: two main product valves, which are normally closed (NC), and two small leakage detection valves, which are either normally open/normally open (NO/NO) or normally closed/normally open (NC/NO). The valve can also be fitted with the Alfa Laval ThinkTop V50 and V70 for sensing and control of the valve.

Working Principle

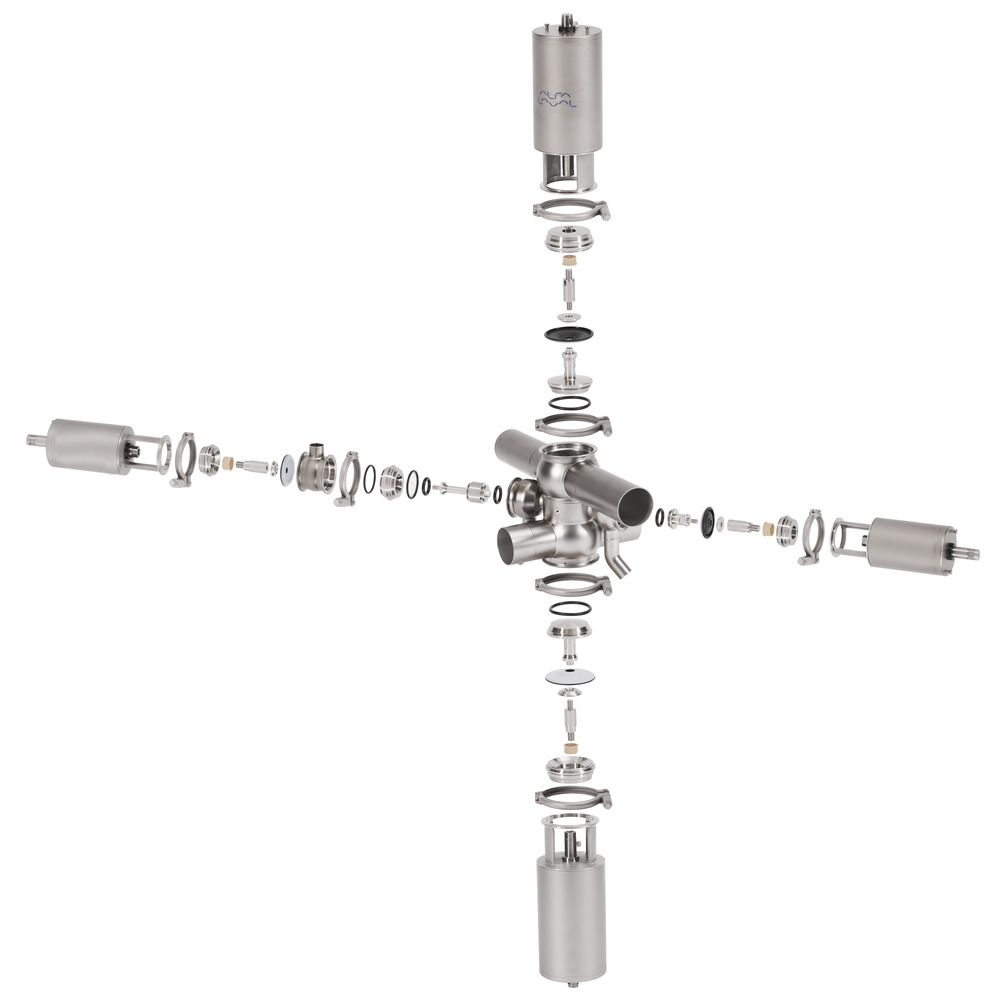

The Alfa Laval Aseptic Mixproof Valve is comprised of a series of base components, including valve body, valve plug/diaphragm, actuator, and cleaning options and accessories that support a wide range of aseptic applications. Composed of a PTFE face and reinforced EPDM backing, the diaphragm creates a hermetic seal to ensure aseptic processing conditions.

Leakage detection holes enable visual inspection without requiring valve disassembly and provide advanced notification of parts wear. Few straightforward moveable parts contribute to reliable operation and reduced maintenance costs.

Certificates

Authorized to carry the 3A system

Alfa Laval ThinkTop V50 and V70

The valve can also be fitted with the Alfa Laval ThinkTop V50 and V70 for sensing and control of the valve.

Technical specifications

-

Product codeID-001

-

TemperatureTemperature range: -10°C to +140°C (EPDM)

Max. sterilization temperature (<1 min): 150°C/380 kPa (3.8 bar) -

PressurePressure range: 0-800 kPa (0-8 bar)

Air pressure: 500-700 kPa (5-7 bar)

Pressure range, support air: 0-300 kPa / 0-3 bar

Materials

Product wetted steel parts: 1.4404 (316L)

Other steel parts: 1.4301 (304)

Product wetted seals: EPDM

Optional product wetted seals: HNBR

Other seals: NBR

Diaphragm: PTFE (Product wetted side) / EPDM