- Long-lasting, spillage-free operation and minimal risk of product contamination thanks to state-of-the-art double-seat design.

- Safe and hygienic operation with added protection of double lip seals

- Easy and fast maintenance due to top-loaded design

- Ease of operation – no adjustable components, a maintenance-friendly actuator and built-in leakage detection on all seals

- Cost effective – a single Unique Mixproof valve can often replace two or more other types of valve

Hotline: (84.0) 906 803 393

Hotline: (84.0) 906 803 393

Product detail

-

Product codeMixproof valves

-

APPLICATIONSSafe separation of different fluids in valve clusters to minimize space requirements.

Concept

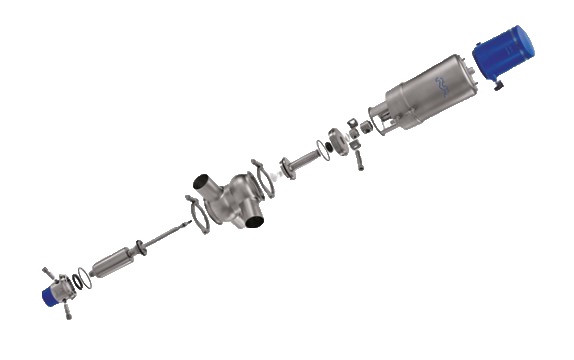

The Unique Mixproof Valve is designed with user flexibility in mind. The customer can choose additional options as required individually; for example higher hygiene demands or higher resistance against physically tough conditions.

Working Principle

Unique is remote-controlled by means of compressed air. The valve is a normally closed (NC) valve.

The valve has two independent plug seals, forming a leakage chamber between them under atmospheric pressure during every working condition. In case of rare accidental leaking of product, this will flow into the leakage chamber and be discharged through the leakage outlet. When the valve is open, the leakage chamber is closed. The product can then flow from one line to the other.

The valve can be cleaned and water hammer protected to any level according to the needs in the specific process (see next page). There is virtually no spillage of product when operating the valve.

ThinkTop V50 and V70

The modular concept of these shut-off valves enables you to tailor them to your specific requirements and only pay for features and capabilities you need. You get the full benefit of the Unique Mixproof valves by combining them with Alfa Laval ThinkTop v70 sensing and control units.

Technical specifications

-

Product codeMixproof valves

-

Pressure:1000 kPa (10 bar)

-

Temperature range:-5°C to +125°C (Depending on rubber quality)

Materials

Productwetted steel parts: . . . . . . . . . . . 1.4404 (316L).

Other steel parts: . . . . . . . . . . . . . . . . . 1.4301 (304).

Surface finish choose from the following:

Internal/external semi-bright . . . . . . . . . . Ra< 1.6

Internal Bright (polished) . . . . . . . . . . . . . Ra< 0.8

Internal/external Bright (internal polished) . . Ra< 0.8

Note! The Ra values are only for the internal surface.

Productwetted seals: . . . . . . . . . . . . . . EPDM.

Other seals:

CIP seals: . . . . . . . . . . . . . . . . . . . . . . EPDM.

Actuator seals: . . . . . . . . . . . . . . . . . . . NBR.

Guide strips: . . . . . . . . . . . . . . . . . . . . PTFE

Cost effective mixproof valve

Alfa Laval Unique mixproof valves feature two independent plugs, which means that a single Unique mixproof valve can often replace two or more valves of other types.

Easy valve to maintain and clean

Unique mixproof valves feature a top-loaded design, making maintenance fast and easy. It also features no adjustable components, a maintenance-friendly actuator and built-in leakage detection on all seals. Unique mixproof valves meet most hygienic standards and can be supplied with the optional SpiralClean cleaning system.

Valve clusters - customized flow solutions

We are specialists in providing pre-built valve clusters customized to meet specific, individual requirements.

Our expertise helps ensure you the most efficient flow management, using as few components as possible and dealing effectively with key issues that include thermal cycling, cleanability, drainability and flow control.

Alfa Laval valve clusters can be supplied pre-assembled and pre-tested as well as fully wired and with all the necessary pneumatic tubing, junction boxes and control panels pre-connected. This means you can bring even complex installations online as quickly as possible, saving time and avoiding lost revenue associated with on-site troubleshooting and downtime.