We offer a wide range of well-proven diaphragm valves. They are built on a modular design and can be configured to meet to any specific requirement.

Alfa Laval diaphragm valves are ideal for use in sterile and ultra-hygienic processes and supplied with a comprehensive documentation package, Alfa Laval Q-doc, providing full transparency of sourcing, production and supply chains, and traceability of all changes in material, manufacturing procedures or spare parts.

Hotline: (84.0) 906 803 393

Hotline: (84.0) 906 803 393

Product detail

-

Product codeAlfa Laval DV-ST

-

CAPACITY5,000 l/h – 40,000 l/h

-

APPLICATIONSThe valves are primarily used in biotech and pharmaceutical industries however they are also widely used in aseptic and hygienic processes as well as in utility systems within dairy, beverage and food industries.

Working principle

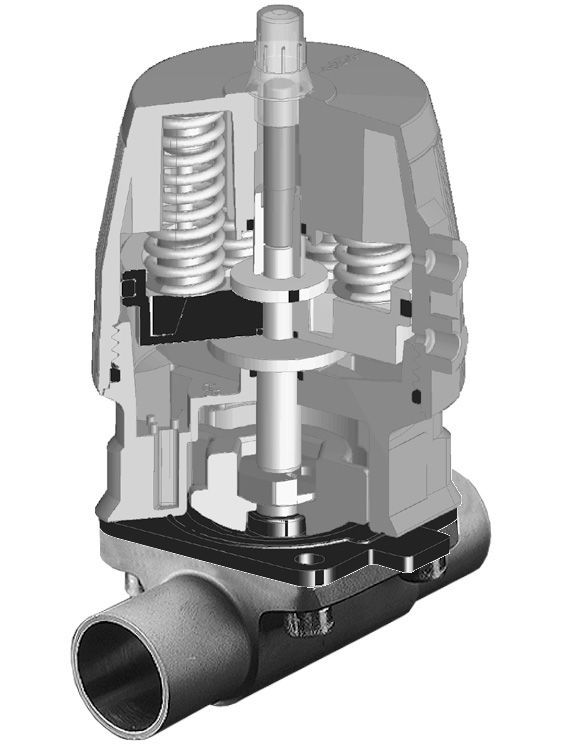

Manual operation

A simple turn of the handle will push the compressor downwards on the diaphragm, pressing the diaphragm against the weir of the valve body thereby closing the valve

Pneumatic operation

The actuator controls the axial movement of a piston, thereby opening or closing the valve depending on the actuator function.

Unique DV-ST UltraPure valve technology

Valve bodies have low delta-ferrite content and defined sulphur content as standard in all forged and block valves. Two-way valves, including the ferrules for clamp-end bodies, are made from a single piece of metal. T- and tank-outlet valves are available machined from block in a multitude of configurations and materials.

The aseptic diaphragm valves are built around a weir-type design and is available with hard or soft compounds from PTFE with EPDM as backing to a pure EPDM diaphragm. They can be operated manually or with pneumatic actuators that come with a range of sensing and control equipment, including control units, position indicators, stroke limiters and valve positioners.

Service and reliability

The valves come with Alfa Laval Q-doc, a comprehensive documentation package that provides full transparency of the entire supply chain. This helps smooth purchasing and installation procedures and facilitates qualification, validation and change control procedures. Based on GDP, Q-doc covers every aspect of biotech and pharmaceutical equipment supply and provides customers with transparent and well-documented quality assurance of the sourced equipment.

Technical specifications

-

Product codeAlfa Laval DV-ST

-

ActuatorThe actuator operates at up to 10 and 6 bar depending on diaphragm material (EPDM and PTFE/EPDM: 10 bar; TFM/PTFE: 6 bar)

-

APPLICATIONSThe valves are primarily used in biotech and pharmaceutical industries however they are also widely used in aseptic and hygienic processes as well as in utility systems within dairy, beverage and food industries.

Documentation

All UltraPure valves are delivered with our comprehensive Q-Doc

documentation package, which includes:

• 3.1/ MTR traceability certificate corresponding to EN 10204

• FDA - Declaration of conformity to FDA

(CFR 21: 177.2600 or 177.1550)

• USP-Certificate of conformity to USP Class VI

(Chapter 88, biological reactivity test)

• TSE/ADI -Declaration

(Transmissible Spongiform Encephalopathy/Animal Derived

Ingredients)

• Surfacefinish conformity declaration

The following documentation is available upon request:

• Surfacefinish certificate (Ra test results)

• ATEXcertificate

Handle and actuator:

The diaphragm valves can be operated by a handle or a pneumatic actuator. Alfa Laval offers 2 different types of manual handles and 1 type of pneumatic actuator.