Application:

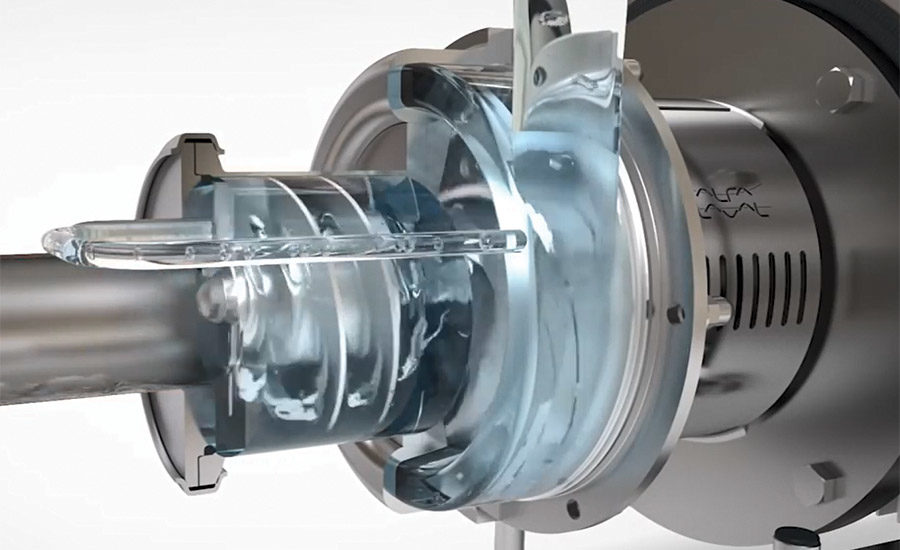

LEMD liquid ring vacuum pumps are displacement single-stage pumps to handling and exhausting of dry and humid gases, entrained liquid can be handled during normal duty.

Hotline: (84.0) 906 803 393

Hotline: (84.0) 906 803 393

Product detail

-

Product codeFlowserve SIHI - LEMD Liquid ring vacuum pumps

-

CAPACITYSuction volume flow: up to 450 m³/h, Suction pressure: 33 up to 1013 mbar

-

APPLICATIONSLEMD liquid ring vacuum pumps are displacement single-stage pumps to handling and exhausting of dry and humid gases, entrained liquid can be handled during normal duty.

Benefits

Non-polluting due to nearly isothermal compression

Oil-free, as no lubrication in the working chamber

Handling of gases and vapours

Small quantities of entrained liquid can be handled

Easy maintenance and reliable operation Low noise and nearly free from vibration

Incorporated central drain

No metallic contact of the rotating parts

Shaft seals

The LKH Prime is equipped with either an external single or a double mechanical shaft seal. Both have stationary seal rings made from stainless steel AISI 329 with sealing surface in silicon carbide and rotating seal rings in carbon as standard.

Technical specifications

-

Product codeFlowserve SIHI - LEMD Liquid ring vacuum pumps

-

CAPACITYSuction volume flow: up to 450 m³/h, Suction pressure: 33 up to 1013 mbar

-

APPLICATIONSLEMD liquid ring vacuum pumps are displacement single-stage pumps to handling and exhausting of dry and humid gases, entrained liquid can be handled during normal duty.

Features

Material housing: Stainless steel (SS) or Cast iron (GG)

Material impeller: Stainless steel or Duplex (SS)

Maximum admissible temperature: 80 degree C

Standard IEC-motor with IE3. Can be configured with; IE4, NEMA, ATEX, CSA, UR, CC etc.

60Hz has CSA and UL as standard

Voltage tolerances as per IEC 60034-1, long-term ±5%, short-term ±10%

Motor bearings greased for lifetime

Min/Max speed

-Air evacuation: 2800-3600 rpm

-Pumping product (no air): 900-3600 rpm

Motor

Foot-flanged motor with a fixed angular contact bearing according to

the IEC metric standard, 2 poles = 3000/3600 rpm at 50/60 Hz, IP 55

(with drain hole sealed with labyrinth plug), insulation class F.

Double mechanical shaft seal

-Water pressure inlet: Max. 500 kPa (5 bar)

-Water consumption: 0.25 - 0.5 l/min

OPERATING DATA

Pressure

-Max inlet pressure: 500 kPa (5 bar)