The LKH pump is a highly efficient and economical centrifugal pump which meets the requirements of sanitary and gentle product treatment and chemical resistance.

LKH is available in thirteen sizes, LKH-5, -10,-15, -20, -25, -35, -40, -45, -50, -60, -70, -80 and -90.

The LKH pump is designed for CIP with emphasis on large internal roundings and cleanable seals.

Hotline: (84.0) 906 803 393

Hotline: (84.0) 906 803 393

Product detail

-

Product codeLKH

-

CAPACITY5,000 l/h – 40,000 l/h

-

APPLICATIONSFormulated dairy products

High efficiency

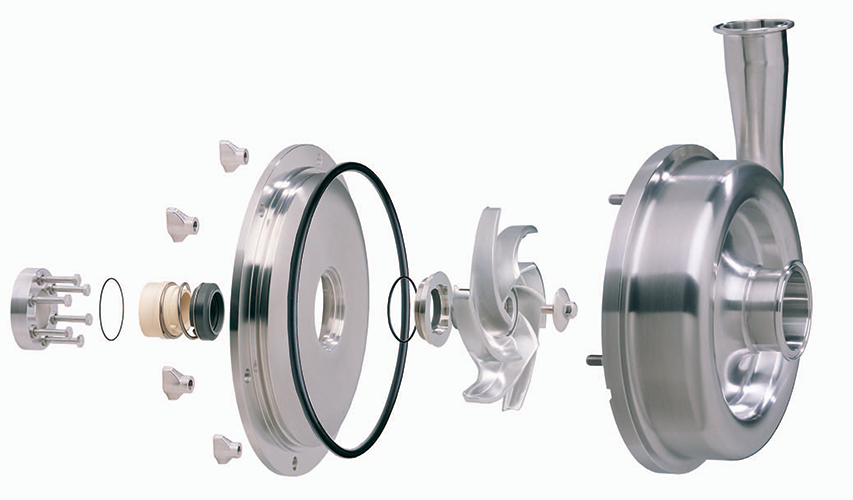

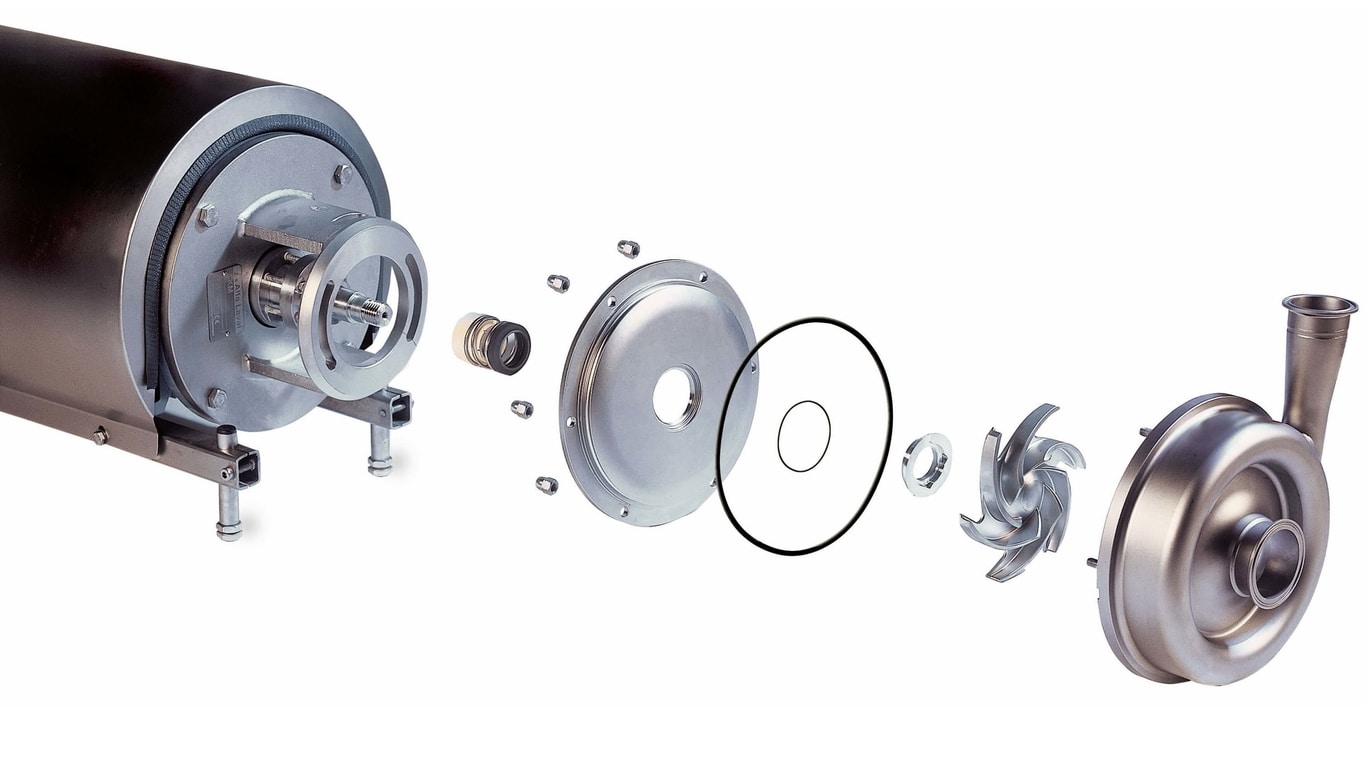

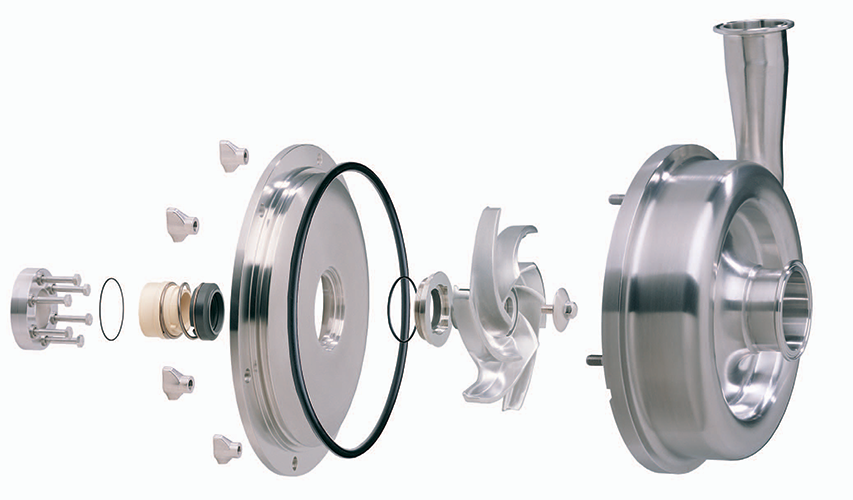

A precision-engineered pump and motor provide high efficiency and gentle product treatment. The robust design and tight tolerances together with the advanced impeller design minimize recirculation and ensure the efficient transfer of energy.

Optimal pump design

The impeller design ensures efficient and gentle handling of the product as it moves through the pump. This ensures product integrity and minimizes NPSHr ( Net Positive Suction Head required).

Low energy consumption

Making pump energy use more efficient presents huge potential for energy savings. The optimized pump design and premium motor of Alfa Laval LKH centrifugal pumps often deliver greater energy efficiency than similar premium pumps and up to 50% compared to similar mid-range pumps.

Cleanability and hygienic design

The key is the attention to detail. Controlled compression gaskets, crevice free internals, an external mechanical seal, and an optimised impeller with balancing holes all ensure that the pump is truly cleaned during a time effective CIP cycle. Perfectly aligned components and joints with O-rings tightened to a predefined compression minimize the elastomer product contact surfaces, which also safeguards hygiene.

Technical specifications

-

Product codeID-001

-

CAPACITY5,000 l/h – 40,000 l/h

-

APPLICATIONSDesigned to meet the hygienic requirements of the dairy, food and beverage and personal care industries

Materials

Product wetted steel parts: . . . . . . . . W. 1.4404 (316L).

Other steel parts: . . . . . . . . . . . . . . Stainless steel.

Finish: . . . . . . . . . . . . . . . . . . . . . Standard blasted

Product wetted seals: . . . . . . . . . . . EPDM rubber.

Motor

Foot-flanged motor according to the IEC metric standard, 2 poles = 3000/3600 rpm at 50/60 Hz, 4 poles = 1500/1800 rpm at 50/60 Hz, IP 55 (with drain hole with labyrinth plug), insulation class F.