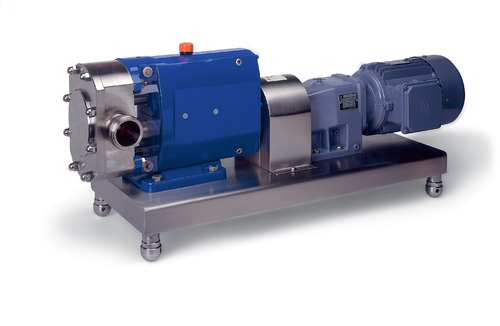

Alfa Laval SRU rotary lobe pumps are carefully engineered to provide reliable performance, trouble-free operation and superior energy efficiency for demanding applications. It is an excellent choice for duties that require contamination-proof pumps to meet high standards of hygiene, low-shear and low-pulsation operation.

This EHEDG-approved pump handles both Cleaning in Place and Sterilization in place, and can be supplied with thorough documentation to support rigorous validation requirements.

Product benefits

- Consistent performance

- Minimal risk of contamination

- Low maintenance

Hotline: (84.0) 906 803 393

Hotline: (84.0) 906 803 393

Product detail

-

Product codeAlfa Laval SRU Rotary Lobe Pump

-

CAPACITYup to 106 m3/h

-

APPLICATIONSViscous products with and without particles, yoghurt, jam, whey/curd mixture, etc

Consistent performance, minimal risk of contamination

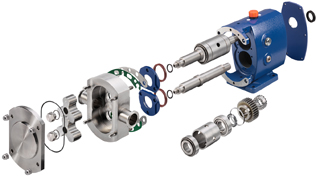

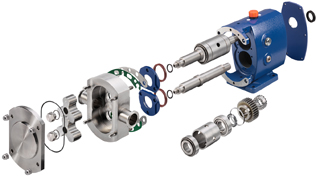

SRU rotary lobe pumps are designed with features that maximize performance and minimize the risk of contamination. These include a defined compression front cover sealing, rotor nut retention design, drainable pump head and ultra-clean surface finishes.

Safeguarding product quality

Understanding of flow patterns is vital to ensure high efficiency fluid transfer with low pulsation, low shear and low noise characteristics. Alfa Laval employs Computational Fluid Dynamics (CFD) to establish exact geometry for the rotors and rotor case.

Greater flexibility and application fit

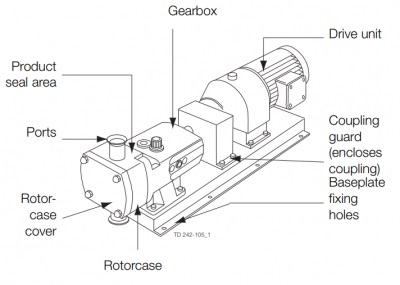

The modular design of the SRU provides greater flexibility to configure exactly the right solution for specific process requirements.

To meet different process requirements, the SRU features an R90 external shaft seal, which may be specified in various materials and configurations in order to ensure the correct shaft seal for the application. Alternatively the SRU can be fitted with Hyclean mechanical seals as well as other seal solutions.

Horizontal or Vertical Porting

SRU pumps are available in both horizontal and vertical port configurations with progressive port sizes and connection options to provide maximum compatibility with existing installations and processes.

Technical specifications

-

Product codeAlfa Laval SRU Rotary Lobe Pump

-

CAPACITYup to 106 m3/h

-

APPLICATIONSViscous products with and without particles, yoghurt, jam, whey/curd mixture, etc

Materials

Product wetted steel parts: . . . . . . . . W. 1.4404 (316L).

Other steel parts: . . . . . . . . . . . . . . Stainless steel.

Finish: . . . . . . . . . . . . . . . . . . . . . Standard blasted

Product wetted seals: . . . . . . . . . . . EPDM rubber.

Motor

Standard foot-flanged motor acc. to IEC metric standard 4 pol = 1500/1800 rpm. at 50/60 Hz.

IP55 (with drain holes with labyrinth plug), insulation class F.