The OptiLobe Rotary Lobe Pump is designed for gentle product treatment in general applications across the dairy, food, beverage, home and personal care industries.

Benefits:

• Cost-effective, hygienic pump.

• Optimal product quality due to gentle, low-shear operation.

• Robust design for long service life.

• Easy maintenance due to self-setting, front-loading seals.

• Low total cost of ownership.

Hotline: (84.0) 906 803 393

Hotline: (84.0) 906 803 393

Product detail

-

Product codeAlfa Laval OptiLobe Rotary Lobe Pump

-

CAPACITYup to 77 m3/h

-

APPLICATIONSThe OptiLobe Rotary Lobe Pump is designed for gentle product treatment in general applications across the dairy, food, beverage, home and personal care industries.

OptiLobe Pump technology

Take advantage of these technological features that enable Alfa Laval OptiLobe rotary lobe pumps add value to your processes.

- A robust platform, advanced seal design and heavy-duty, long-life bearings contribute to more uptime and higher productivity.

- Truly front-loading, self-setting seals with seal faces directly in contact with the media ensures superior cleanability and lubrication, improving seal life.

- Shaft support made of a rigid one-piece bearing housing and heavy-duty L10 tapered roller bearings with a minimum life of 20,000 hours. This contributes to stable shaft retention and more balanced loading, thereby reducing the risk of pump head contact whilst decreasing maintenance requirements and increasing uptime.

- Optional heating/cooling front covers for processes, such as sugar solutions, butter and margarines, marmalades, body butters, gels and lotions, where products tend to harden at low temperatures.

Product models

OptiLobe rotary lobe pumps are available with 10 different pump head displacements based on five different gearbox modules, flow rates up to 77 m3/h, differential pressures up to 8 bar, media temperatures up to 130°C and port size from 25 to 100 mm in diameter.

Operating principle

A gear train in the pump gearbox drives the rotors and provides accurate synchronization of the tri-lobe rotors.

The movement of the counter-rotating rotors creates a partial vacuum that allows atmospheric pressure or other external pressures to force fluid into the pump chamber. As the rotors revolve, an expanding cavity forms, filling with fluid. As the blades disengage, each dwell forms a cavity. As the rotor blades engage, the cavity diminishes and fluid is, displaced into the outlet port.

Part of a broad pump range

Part of the company’s rotary lobe pump range, the Alfa Laval OptiLobe is carefully engineered to provide reliable process performance, trouble-free operation and good energy efficiency in demanding applications. Alfa Laval provides a comprehensive range of hygienic pump technologies and specifications to meet customer demands with regard to preserving product quality, process efficiency, and easy maintenance.

Technical specifications

-

Product codeAlfa Laval OptiLobe Rotary Lobe Pump

-

CAPACITYup to 77 m3/h

-

APPLICATIONSThe OptiLobe Rotary Lobe Pump is designed for gentle product treatment in general applications across the dairy, food, beverage, home and personal care industries.

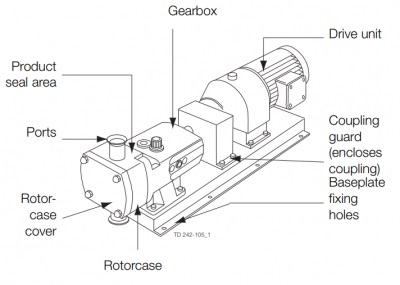

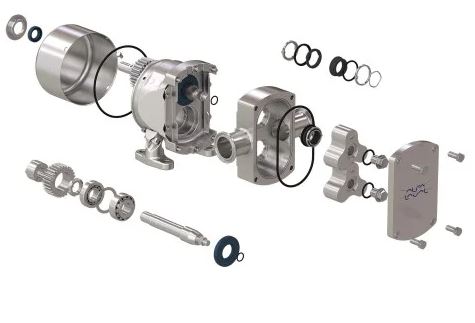

Construction

Alfa Laval rotary lobe pumps are positive displacement pumps with rotor case, rotor case cover, rotors, rotor nuts, shafts, gearbox and shaft seals and elastomers. The pumps operate with no internal contacting parts in the pump head.

The OptiLobe can be supplied either as a bare shaft pump or mounted on a base plate complete with coupling, guard, gear motor and shroud for easy plug-and-play installation.

The standard materials of construction are 316L stainless steel for all wetted parts, all stainless-steel exterior, and EPDM for all product-wetted elastomers. EasyFit shaft seals are fully front-loading, and high-precision machine components are interchangeable for pumps of the same size.

In addition, Alfa Laval manufactures all pump parts, including the rotor case and high-precision rotors. This facilitates maintenance and results in full interchangeability of spare parts.

Motor

Gear motor, 4 poles, to IEC metric standard, 50/60 Hz, suitable for frequency conversion, IP55, insulation class F.

Min/Max speed

-Air evacuation: 2800-3600 rpm

-Pumping product (no air): 900-3600 rpm